Details

- Construction Date 09 Sep 2018

- Category Offshore

Description

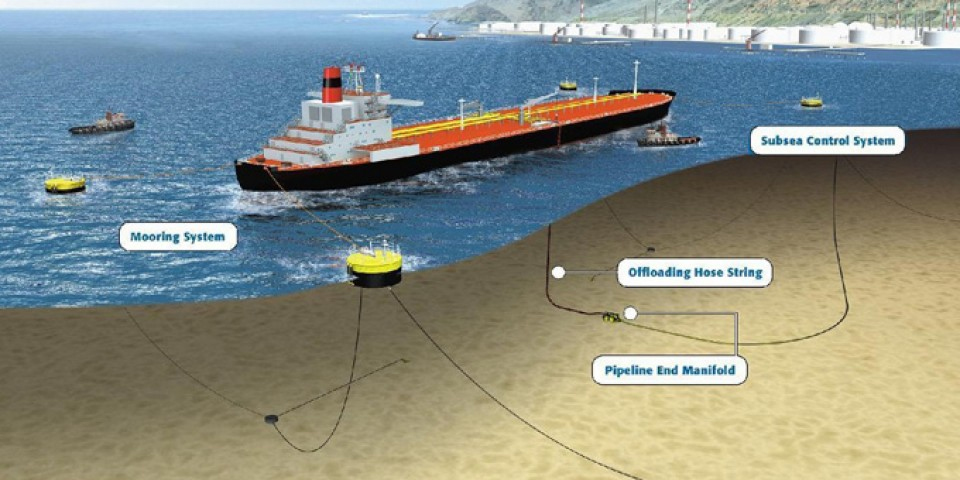

Conventional Buoy Mooring (CBM) systems, sometimes referred to as Multiple Buoy Mooring (MBM) systems, are in use for the transfer of products such as crude and LPG between tankers and shore facilities all over the world.

A CBM system provides a safe and attractive solution to tanker loading / offloading requirements in shallow water, offering a more reliable, efficient and cost effective alternative to jetty systems. (Moreover, offshore terminals give a far greater scope and flexibility for location).

[image url=”http://partoltd.ir/en/wp-content/uploads/2014/11/3.2.1.1-Image-2-CBM-Buoy.jpg” link=”image” video_id=”none” align=”right” alt=”” title=”” width=”300″ height=”248″ border=”0″ lightbox=”1″ crop=”1″]

CBM systems are ideally suited to shallow water applications up to some 30m depth in benign environmental conditions and conditions with a dominant directional character.

With safety and environmental considerations foremost in the design, and a design life of 20 to 25 years, CBM systems assure the integrity and value of your investment.

A Conventional Buoy Mooring (CBM) system restricts tankers from weather vanning and, as such, it is often applied on projects where smaller tankers are employed, in areas where the environmental conditions are moderate or directional and / or where the frequency of loading / offloading operations is limited.

The system can be designed to berth all sizes of tankers but, in general, tanker size Typically ranges from 5,000 to 60,000 DWT.

The CBM system allows the tankers to safely maintain position for the period required to load or offload their products. Typically, 3 or 4 mooring buoys are used for station keeping of the tanker. When berthed, the tanker remains on location without using its own anchors. On the tanker side, the ships mooring ropes are connected on either side to the bow and the stern and on the buoy side to the quick release hooks on the buoy. After mooring the tanker to the buoys, picking up a submerged hose string and connecting this hose to its mid ship manifold, the loading or offloading operation may start. The other end of the hose string is connected to a Pipeline End Manifold (PLEM), which in turn is fixed to a subsea pipeline, transferring the product to or from any installation located onshore.

On completion of the loading operation, the hose string is laid down on the seabed, ready for being picked up again when the next tanker arrives.

A Conventional Buoy Mooring (CBM) system typically consists of the following main components :

- Mooring system with buoys, mooring legs and anchor points

- Pipeline End Manifold (PLEM) and pipeline to shore

- Subsea control system

- Hose string with pick-up arrangement