Details

- Construction Date 09 Sep 2018

- Category Offshore

Description

Why is it called pigging?

The theory is that two pipe liners were standing next to a line when a pig went past. As the pig travelled down the line pushing out debris, one of them made the comment that it sounded like a pig squealing. The pig in question consisted of leather sheets stacked together on a steel body.

Another theory is that PIG stands for Pipeline Intervention Gadget.

Why pig a pipeline?

The earliest pigs are believed to have been made on site from straw wrapped with barbed wire.

During the 1940s pipelines were mainly pigged to remove paraffin to increase efficiency in crude oil pipelines in order to maximize flow conditions for the war effort.

The pigging equipment utilized at that time was limited to a few applications while being very crude in nature.

In today’s world, pipelines are pigged for a variety of reasons and the pigging equipment used is designed by engineers to perform particular functions.

Type of pigs:

Pigs can be broadly divided into three categories:

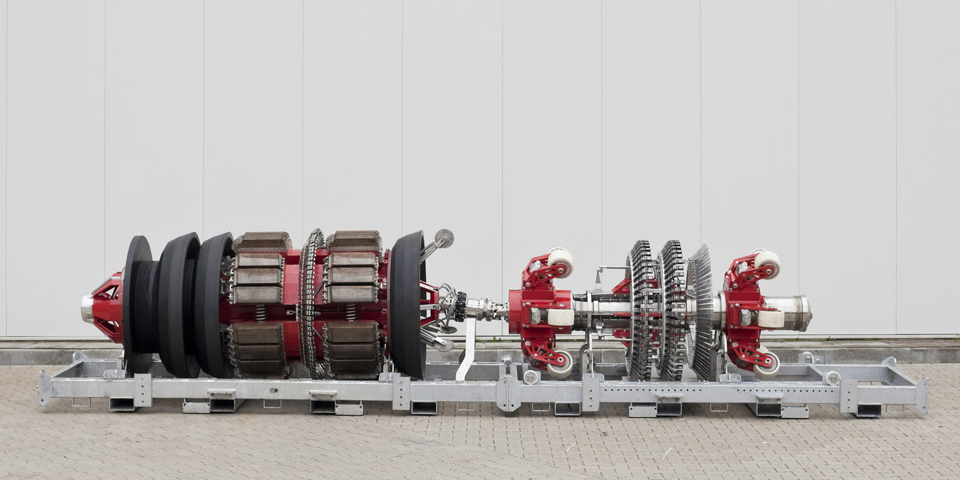

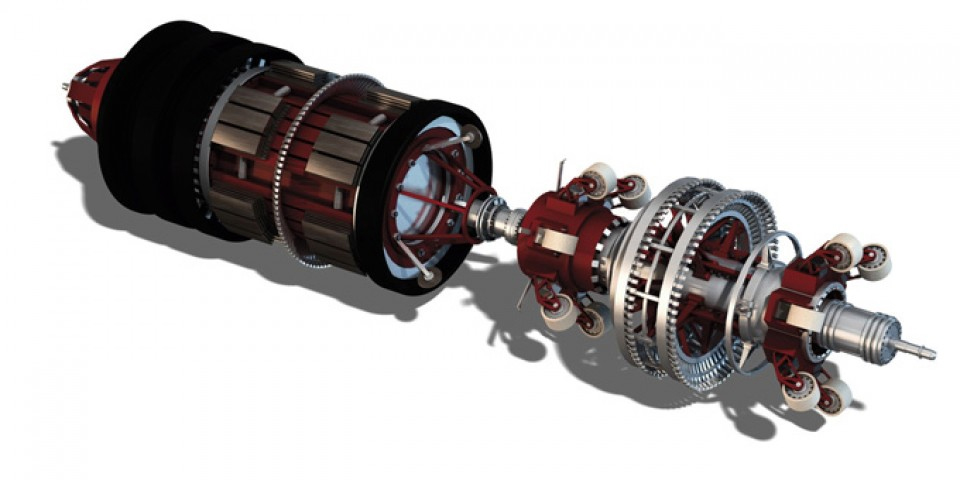

Utility pigs: which are used to perform functions such as cleaning, separating, or dewatering.

In line inspection tools: which provide information on the condition of the line, as well as the extent and location of any problems.

Gel pigs: which are used in conjunction with conventional pigs to optimize pipeline dewatering, cleaning, and drying tasks.

Plugs: isolate a section of the pipeline.

Piggability & Pig Selection

The type of pig to be used and its optimum configuration for a particular task in a particular pipeline is determined based upon several criteria, which include:

The Purpose:

Type ,location, and volume of the substance to be removed or displaced in conventional pigging applications,

Type of information to be gathered from an intelligent pig run,

Objectives and goals for the pig run.

The Line Contents:

The contents of the line while pigging,

Required driving pressure, velocity of the pig

Characteristics of the Pipeline

The minimum and maximum internal line sizes,

Maximum distance pig must travel,

Minimum bend radius, and bend angles,

Additional features such as valve types, branch connections, and the elevation profile.