Details

- Construction Date 04 Sep 2018

- Category Onshore

Description

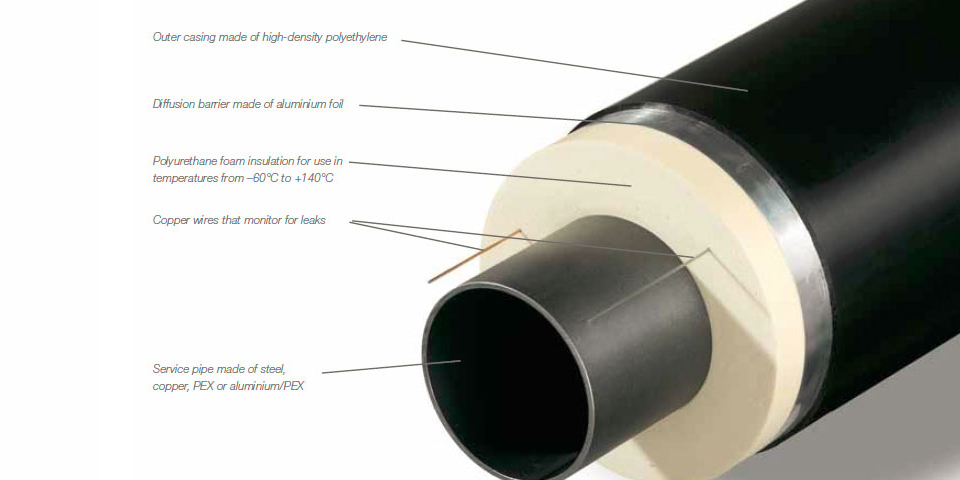

Pre-insulated pipe systems that are the safest, most cost-effective way of transporting liquids and gases with temperatures ranging from –200°C to80°C by pipe, with the absolute minimum of energy loss. Our current production amounts to more than 10,000 kmper year. The heart of all pre-insulated pipe systems is the unique Polyurethane cellular foam. This provides completely consistent, highly effective thermal protection around the service pipe, keeping any energy loss to the absolute minimumpre-insulated pipe systems, all the difficult work has already been done when the pipes arrive on site. You just join together the fully finished pre-fabricated sections, using a few easy, rapid procedures. Using pre-insulated pipe concept, your LNG terminal pipeline gets to function within weeks rather than years.

Pre-insulated pipe concept makes your entire terminal pipeline one single bonded system. A special low-temperature version of our unique polyurethane (PUR) cellular foam is used, and this is bonded to both the service pipe and the outer casing.

The composition of this insulation foam makes it strong and flexible enough to absorb the forces created by the steel service pipe expanding and contracting, and to transmit them to the outer casing. The entire system behaves as one unit, and there is no stress-inducing movement of the service pipe within the insulation.

Advantages:

- The only on-site insulation work is the installation of a relatively small number of joints, using rapid, Foolproof foaming procedures.

- Insulation covering the joints is just as effective as that in the pipe lengths.

- Individual pipe lengths are connected with electrically welded joints, using field proven, quality-assured procedures.

- The pipe supports are positioned on the outer casing, which eliminates any thermal bridging.

- No problems with seepage or ice formation, regardless of weather or climate.